Originally, it appears there were 35 sheets but they were later formatted onto 18 sheets. Additionally, some of the M Drawings are now posted on the Cozy Builder site. There are updates to multiple templates. Updated plans should have a "G" template for setting the canard incidence. The rib R57 for the strake is updated with 1/2" loft.

Links here:

Cozy Builder CAD files - updated M drawings

http://www.cozybuilders.org/cad_files/Cozy_MKIV_M-Sup_1.2_Draft.pdf

New Sheet Contents

1 Right, Top Instrument Panel & Top Seatback

2 Left, Top Instrument Panel & Bottom Seatback

2 Right, Bottom Instrument Panel, & M-23 & M-24 Match Pieces

3 Right Bulkheads F-22 and F-28

4 Left Landing Gear 2

4 Left Landing Gear 1

5 Right, Top Firewall

5 Right, Bottom Firewall

8 Fuselage Cross Section - FS 105 to FS 124

6 Fuselage Cross Section - FS 2 to FS 20

6 Fuselage Cross Section - FS 20 to FS 35

7 Fuselage Cross Section - FS 35 to FS 52

7 Fuselage Cross Section - FS 52 to FS 69

7 Fuselage Cross Section - FS 69 to FS 86

8 Fuselage Cross Section - FS 86 to FS 105

9 NACA Templet, Top and Bottom Fuselage Contour Templets

10 Canard Templets

10 Canard Elevator Templets, Vortilon Templets

11 Nose Sections

12 Wing Jig Templets #3, #4, #5 Match Pieces, CS Spar Templets & Winglet Trim Templet

12 Wing Jig Templets #1, #2, #3 & #4 Match Pieces, Rudder Conduit Pattern, & Winglet Root Match Templet

12 Wing Jig Templets #1, #2, #3 & #4 Match Pieces, Rudder Conduit Pattern, Winglet root Match Templet & Winglet Tip Templet

13 Wing Templets BL 67.5, 118.25 & 169 Match Pieces & Straight Templet

13 Wing Templets BL 31, 67.5 & 118.25 Match Pieces & Aileron and Torque Tube Templets

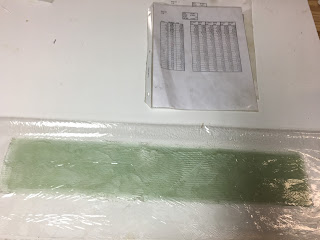

14 Fuel Tank Rib R-33, R-57 Match Pieces & Winglet Bottom Tip Templet

15 Canopy Frame Templets FS 41, 50, 50 & 70 & Canopy Brace

11 Speed Brake Details

16 Engine Mount Front and Side Views

17 Engine Baffles

18 Engine Baffles

18 Carburetor Filter Box