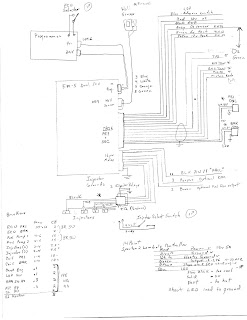

Typical mags fire the top plugs on one side and bottom plugs on the other side. I looked at one of the older Jeff Rose EI systems and it is wired this way. The Fly EFII system specifies top plugs to one coil and bottom plugs to the other coil. The ignition switch on traditional aircraft have Off/Left/Right/Both. I'd noticed that some experimental/home built aircraft switches were labeled Top/Bottom.

The cylinder cooling fins have different depths on the left/right sides of the barrel.

This is my supplemental builders blog for a Cozy Mark IV which is a 4-seat, single engine, homebuilt light aircraft designed by Nat Puffer, with parts and plans supplied by Aircraft Spruce & Specialty Co. The aircraft is built from plans using basic raw materials. It is not a kit aircraft, though many small parts are available prefabricated. The Cozy is similar in design and construction to the 2-seat Rutan Long-EZ, from which it is derived, with approval from Burt Rutan.

Pages

Chapters (Blogger Labels)

- Chapter 01 Description and Introduction

- Chapter 02 Bill of Materials

- Chapter 03 Education

- Chapter 04 Fuselage Bulkheads

- Chapter 05 Fuselage Sides

- Chapter 06 Fuselage Assembly

- Chapter 07 Fuselage Exterior

- Chapter 08 Head Rest and Seat Belts

- Chapter 09 Main Gear & Landing Brake

- Chapter 10 Canard

- Chapter 11 Elevators

- Chapter 12 Canard Installation

- Chapter 13 Nose - Nose Gear & Brakes

- Chapter 14 Center Section Spar

- Chapter 15 Firewall

- Chapter 16 Control System

- Chapter 17 Pitch and Roll Trim

- Chapter 18 - Canopy

- Chapter 19 - Wings/Ailerons/Attach

- Chapter 20 - Winglets & Rudders

- Chapter 21 - Strakes

- Chapter 22 Electrical System

- Chapter 23 - Engine Installation

- Chapter 24 Armrests Seats Fairings

- Chapter 25 - Finishing

- Chapter 26 Upholstery

- Cozy Builders

- EAA

- FAA

- Flight Testing

- Landing Brake and Center Console

- M Drawings

- Maintenance

- mods

- Skunk Works

- Trip reports

- Wheel Pants

Sunday, December 16, 2018

Sunday, November 11, 2018

Sunday, November 4, 2018

Things I learned this week....

You can't cut stainless steel with an Oxy-Acetylene torch. The metal pools and blobs fly when you hit it with Oxygen. Oddly after discovering this, I found this video titled Dummy trying to cut stainless with a torch.

The Type - K yellow insulated lead thermocouple wire can't be soldered with rosin core solder. It's made of nickel and chromium. There's a new Type N wire. http://www.thermometricscorp.com/thertypk.html

If you make a joke (regarding aviation) on social media, someone might complain to the FAA and they're obligated to investigate. Recent account from YouTube "Just Plane Silly" channel story here: https://youtu.be/P0Fs_RI4Hok

The Type - K yellow insulated lead thermocouple wire can't be soldered with rosin core solder. It's made of nickel and chromium. There's a new Type N wire. http://www.thermometricscorp.com/thertypk.html

If you make a joke (regarding aviation) on social media, someone might complain to the FAA and they're obligated to investigate. Recent account from YouTube "Just Plane Silly" channel story here: https://youtu.be/P0Fs_RI4Hok

Tuesday, September 25, 2018

Chapter 15 Firewall & 22 Electrical - EI/EFI, Dynon EMS, ACK ELT, Princeton Fuel module mounting

The Dynon EMS module and SDS EI/EFI modules need to be mounted on the cold side of the firewall. Mounting them on a removable shelf that is cut to still allow quick access and inspection of the engine mounting bolts and hard points should provide for easy maintenance and changes to be made in the future if needed.

|

| The ELT needs clearance for the antenna, and two small cables (DIN for GPS and remote panel). |

|

| The dual SDS controller has two relays that also need to be mounted. There are 6 connectors on this module. |

|

| The rectangular hole for the bulkhead connectors and round hole for cabin heat are visible here. |

|

| A couple of removable plugs for leg bow inspection were made by using a 4.5" hole saw and cutting from scraps of left over strake material. The foam will be microed. |

|

| BID covered strake foam shelf was bonded to the round covers with West 704 filler. |

|

| The Princeton modules will mount on the triangular space. |

|

| The orientation of the modules is limited by the available space. |

|

| Two Amphenol 37 pin connectors are mounted to a plate that covers a rectangular hole that is large enough for the D-connectors to pass through. A nut plate is on the cold side of the firewall. |

|

| Rotation was not limited by the clamp on the torque tube. |

|

| One of the few photos of the Dynon SV32 roll servo. The ELT ground plane (copper foil tape) should be adequate. West 407 filler was used to pot washers. |

|

| Access to the servo is through the opening under the heater duct hole. |

Monday, August 6, 2018

Chapter 22 Electrical System - auxiliary sensors

Unused Dynon EMS ports can be used for additional data.

This would be handy for reading the delta air pressure and temp across the oil cooler, cylinders etc.

http://wiki.dynonavionics.com/Making_your_own_sensor_definitions

http://dynonavionics.com/cgi-bin/yabb2/YaBB.pl?num=1291258674/1#1

http://dynonavionics.com/cgi-bin/yabb2/YaBB.pl?num=1268164287

This would be handy for reading the delta air pressure and temp across the oil cooler, cylinders etc.

http://wiki.dynonavionics.com/Making_your_own_sensor_definitions

http://dynonavionics.com/cgi-bin/yabb2/YaBB.pl?num=1291258674/1#1

http://dynonavionics.com/cgi-bin/yabb2/YaBB.pl?num=1268164287

Monday, June 18, 2018

Chapter 15 Firewall - cutting and fitting

A deviation from plans is to use Stainless Steel rather than Aluminum.

Edit/update - drilling to fast will heat up and dull drill bits. Go slow and apply pressure for better results.

|

| Stainless can be hard to work with. The hole saw grabbed and tore the metal a little here. This hole was just for the knock out bolt. Fortunately, the knock out cut this part out. |

|

| The sheet is clamped in place. The cardboard helps align the knock out. |

|

| A uni-bit seemed to drill holes pretty well without tearing. A sharpie marked the stop depth on the bit. |

|

| Still needing a little trimming, but is lining up pretty well. |

|

| Stainless Steel parts from Cozy Girrrls. Not all holes are drilled. |

|

| Saw this technique either on an EAA video or another metal builder's site. |

|

| Cleco clamps hold the paper to the pulley so the holes can be marked with a sharpie. Small dots mark where the cotter pin holes need to be. |

|

| Keep the drill bit cool (I used water) and take your time. These little holes each took about 10 minutes. Black carbide drills work. The drill press doesn't go slow enough and heats the bit up. |

Wednesday, June 13, 2018

Flight Testing

Links to FAA Flight Testing Advisories:

https://www.faa.gov/news/safety_briefing/2014/media/SE_Topic_11_2014.pdf

https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC%2090-89A.pdf

https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_90-116.pdf

EAA Webinar on the Flight Test Manual:

http://www.eaavideo.org/detail/videos/homebuilding/video/5993410710001/webinar--introducing-the-eaa-flight-test-manual

Here's a link to Kevin Walsh's "Experimental Aircraft Flight Test Protocol":

http://www.cozybuilders.org/docs/Cozy-MKIV_Flight_Test_Protocol.pdf

I'll need to do some editing for mine, but it is really thoughtful of others to share with the group.

I've been reading this and will plan on using the data recording of the Skyview system to help reduce work load. Also think I may ensure the Auto Pilot is working earlier in the protocol to help reduce work load and improve the accuracy of the flight tests.

https://www.faa.gov/news/safety_briefing/2014/media/SE_Topic_11_2014.pdf

https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC%2090-89A.pdf

https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_90-116.pdf

EAA Webinar on the Flight Test Manual:

http://www.eaavideo.org/detail/videos/homebuilding/video/5993410710001/webinar--introducing-the-eaa-flight-test-manual

Here's a link to Kevin Walsh's "Experimental Aircraft Flight Test Protocol":

http://www.cozybuilders.org/docs/Cozy-MKIV_Flight_Test_Protocol.pdf

I'll need to do some editing for mine, but it is really thoughtful of others to share with the group.

I've been reading this and will plan on using the data recording of the Skyview system to help reduce work load. Also think I may ensure the Auto Pilot is working earlier in the protocol to help reduce work load and improve the accuracy of the flight tests.

Adding some notes here that will be incorporated:

Fuel Injection /Electronic Injection - Dual ECU Switch

When running dual ECU boards, this toggle switch activates relays which switch operation of the injectors from one ECU board to the other. In normal operation, one board is always firing the top spark plugs, the other fires the bottom plugs. The ECU select switch only switches the injector connection over to the other board. If one ECU board fails, you’ll lose one set of plugs but the engine should continue to run.

The recommended ECU checking procedure is to start the check on the backup ECU. At idle, Switch the ECU selector switch from Backup to Primary. If the engine continues to run, both ECUs are working. Now you can switch coil power off on the #1 coil pack. Switch that one back on and then switch off #2 coil pack power. If the engine continues to run, both coil packs are working.

Be sure to check that both coil power switches are back on prior to takeoff.

Wednesday, June 6, 2018

Chapter 17 - Vance Atkinson's springboard and electric pitch trim systems

Updated 12/25/2019

Vance later updated to an electric trim system, but a downside was if there was run away trim, needed to be disconnected to allow full elevator travel. He accomplished this with a quick disconnect pin through the Heim joint. We tried different springs to allow full travel if there was run away trim, but Vance did not care for the resulting stiffer/softer forces.

Here's a link to a photo of the plans to make a Davenport spring

Tuesday, May 29, 2018

Chapter 23 Engine Installation - prop, extension, Step 3 cowl

Click on Chapter 23 above to see all of the Chapter 23 posts.

|

| Catto 68" diameter 78" pitch prop with nickel leading edges and erosion tape. |

|

| The blocks had to be moved in order to apply the BID that lays up in front of the cosmetic piece. This particular area of the cowl lips were a little proud and met the wrath of the belt sander. |

|

| Pop sickle sticks and hot glue worked pretty well and was easier to remove than Bondo. |

3 BID curing while the trailing edge is shimmed up to help correct a tendency to sag.

|

| The plans construction method for the cowl lip is to attach foam blocks to the inlet and carve the foam to this shape. I opted to use a 1x2 piece of PVC foam and a belt sander. |

|

| The cowl wasn't made to accomodate the scoop for the NACA inlet. The lip has to come down and inch. I cut the cowl back 7" to help make a ramp for the scoop that won't be to draggy. |

|

| Prepping the foam lip to be glassed in. |

|

| Small fairing blocks on the bottom cowl ramp. |

|

| Two identically shaped blocks will help keep the boat tail cowl in position while the 5 BID inside layup cures. |

Subscribe to:

Comments (Atom)

Relevant links for supplies and other info

- Cozy IV Specs

- Cozy Builders - Google Groups

- Unofficial Cozy Builders Site - updates to plans and much more information (maintained by Marc Zeitlan)

- Cozy Builders Mailing List, POH and other info

- Cozy Builders - Map

- Official Cozy Aircraft Site (outdated site)

- Canard Zone

- Central States Association - Facebook

- COBA Canard Owner and Builder Association

- Builder Sites (maintained by Erland Moen)

- Experimental Aircraft Association

- Rutan Aircraft Flying Museam

- Dennis Butler's Grand Champion

- aerocomposites.aero - Gear legs and fiberglass parts

- Aircraft Spruce Cozy IV Parts

- http://www.wicksaircraft.com/index.html

- 3:23 Composites

- SDS EI EFI

- Cozy Girrrls

- Skycraft Surplus

- www.enginegearonline.com/

- Infinity Aerospace

- NIck's web site

- https://www.stuarthose.com/

- http://www.tostenmfg.com/

- www.eurekacnc.com

- Featherlite (http://aerocad.com) parts

- http://aeroelectric.com/

- www.long-ez.com/

- Earl's Performance Fuel Systems

- FAA Amateur Built Operating Limitations

- FreeFlight Composites

- ADS-B blocking

- FAA - A&P / Experimental Builder Experience

- EZ.ORG moved to ez.canardaircraft.com

- Fiberglass Warehouse

- High Temp Epoxy

- Marc's Nose Gear parts